3D Scanning for Stone Sculpture Replication

Project Overview

LiDAR + Photogrammetry for Digital Fabrication in Stone

MYND Workshop was commissioned by artist Barb Smith to create highly detailed 3D scans of a series of sculptures constructed from foam mattresses. These works contained subtle surface textures, compression marks, cuts, and material irregularities — all of which were essential to preserving the character and intent of the original artwork.

Using a hybrid workflow combining terrestrial LiDAR scanning and high-resolution photogrammetry, we captured the sculptures in extreme detail, producing accurate digital twins suitable for advanced fabrication.

The final deliverables included fully processed, watertight 3D meshes optimized for CNC stone carving.

Foam Sculptures by artist Barb Smith

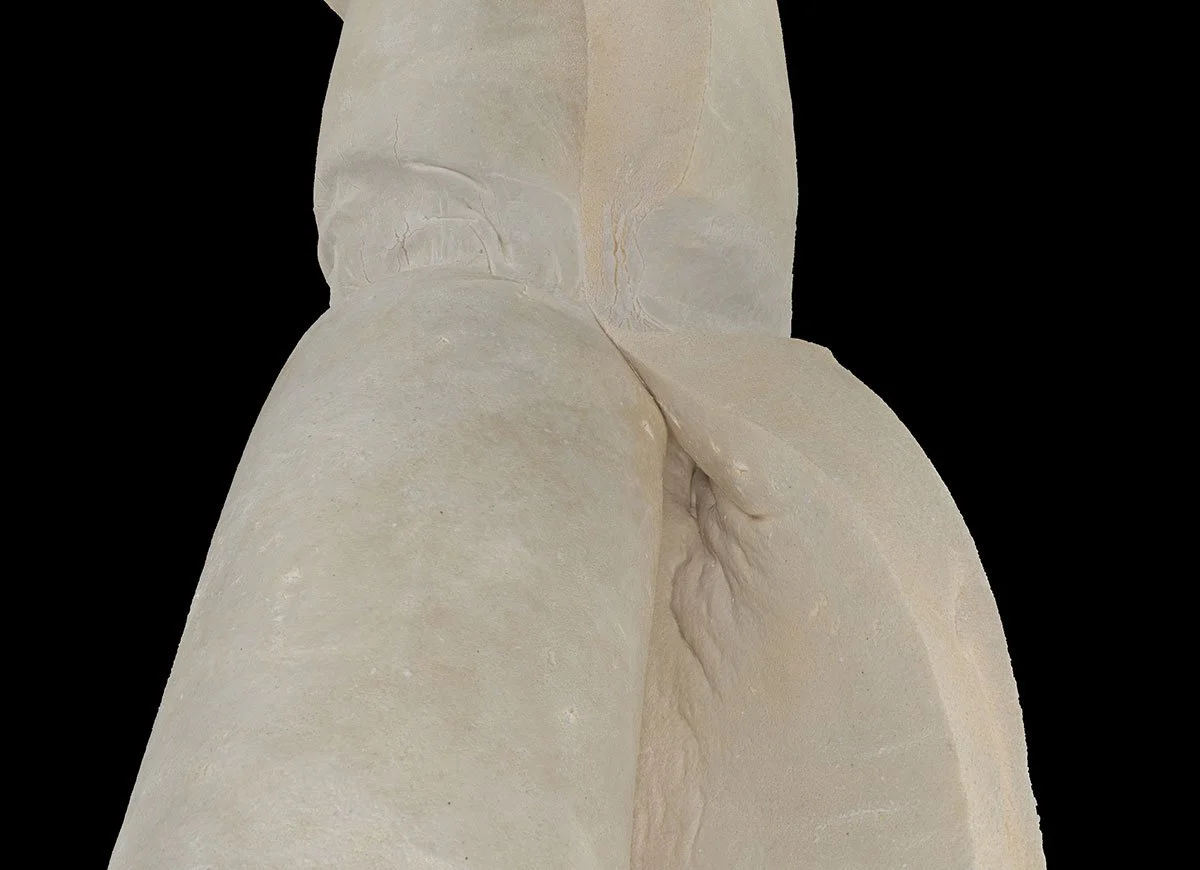

Foam sculpture detail (Barb Smith)

Foam sculpture detail (Barb Smith)

Capturing Surface Character and Detail

Unlike traditional sculptural documentation, this project required:

Preservation of micro-surface detail

Accurate geometry for fabrication

Clean, manifold mesh topology

True-to-life scale for replication

The softness and irregularity of foam material posed a unique challenge. By combining LiDAR for structural accuracy and photogrammetry for fine surface texture, we produced a highly resolved digital replica of each piece.

Every indentation, tear, and compression mark was retained — ensuring that the transition from foam to marble preserved the artist’s original expression.

Detail from 3D Scan of Foam Sculpture by Barb Smith

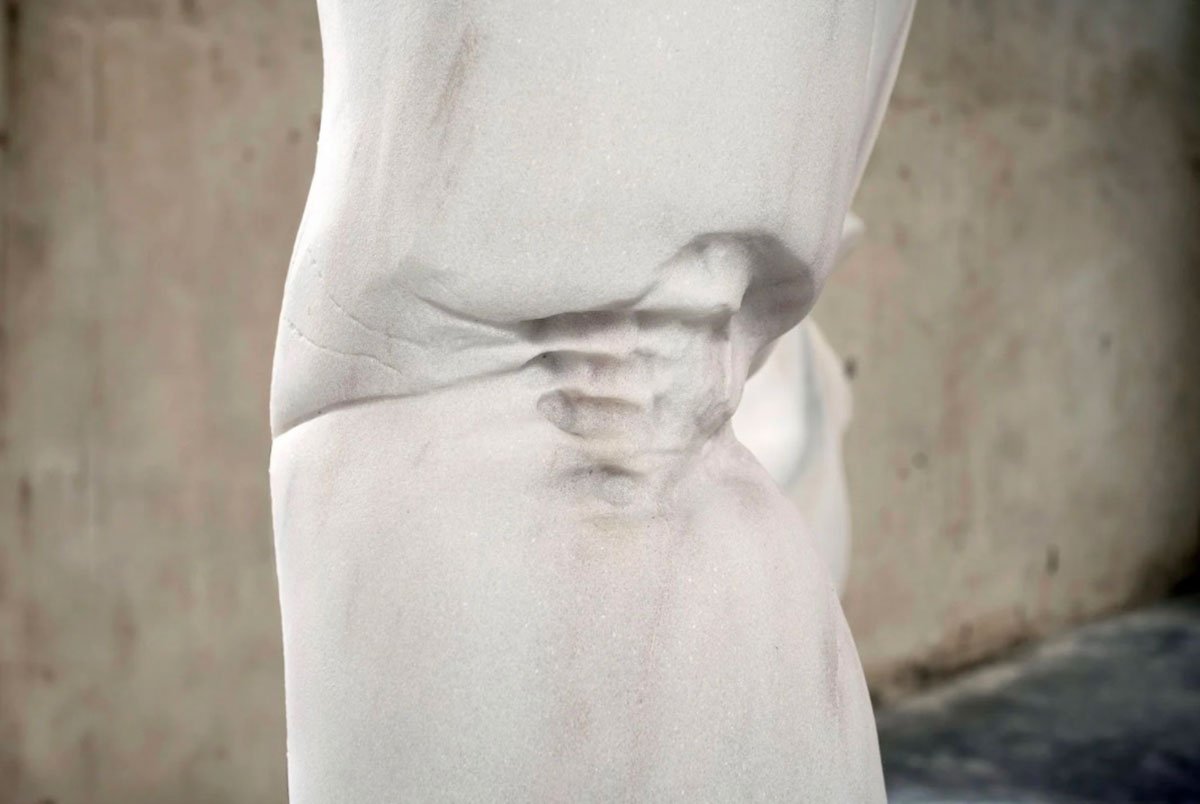

From Digital Twin to Marble Sculpture

The processed meshes were delivered to the artist’s fabricator, where they were used to drive a high-precision CNC stone cutting machine capable of carving marble directly from the 3D model data.

This workflow enabled:

Exact 1:1 scaling

Direct translation from scan to fabrication

Complex organic geometries in stone

Replication without loss of artistic nuance

The result: marble replicas that faithfully reproduce the subtle textures and physical language of the original foam sculptures.

CNC of Marble Sculpture from 3D Scan

CNC of Marble Sculpture from 3D Scan

Video showing CNC process of cutting and finishing marble sculptures produced from 3D scan files. Sculptures by Barb Smith; Scanning by MYND Workshop

Video showing CNC process of cutting and finishing marble sculptures produced from 3D scan files. Sculptures by Barb Smith; Scanning by MYND Workshop

Video showing CNC process of cutting and finishing marble sculptures produced from 3D scan files. Sculptures by Barb Smith; Scanning by MYND Workshop

Finished Marble Sculptures by Barb Smith, Cut using CNC machine from 3D Scans

Detail - Finished Marble Sculptures by Barb Smith, Cut using CNC machine from 3D Scans

Finished Marble Sculptures by Barb Smith, Cut using CNC machine from 3D Scans

Services Provided

High-resolution 3D laser scanning (LiDAR)

Photogrammetry capture and processing

Digital twin creation

Mesh cleanup and repair

Watertight mesh generation for CNC fabrication

Fabrication-ready file delivery

Applications

This project demonstrates how 3D scanning and digital fabrication can support:

Fine art replication

Sculpture preservation

Marble and stone CNC carving

Artist fabrication workflows

Editioned sculpture production

Digital archiving of artworks